What is Cast Stainless Steel?

Cast stainless steel is an alloy produced by melting stainless steel and pouring it into molds with specific shapes and designs. This process enables the creation of complex, customized components while retaining the material’s inherent properties, including corrosion resistance, strength, and durability. It is primarily used in industries where precision and reliability are critical, ensuring optimal performance even in harsh environments.

The Importance of Stainless Steel in Manufacturing

Stainless steel holds a pivotal position in manufacturing due to its combination of strength, corrosion resistance, and versatility. Its durability ensures a long service life, thereby reducing the frequency of replacements or repairs and leading to lower maintenance costs. Furthermore, as stainless steel is easy to clean, hygienic, and capable of withstanding severe environmental conditions, it is widely applicable in fields such as construction, medical equipment, and food processing machinery. For industries prioritizing safety and efficiency, these characteristics make it a reliable and cost-effective choice.

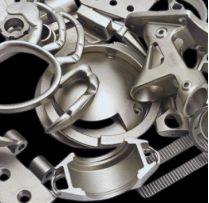

Overview of Casting Techniques

Kum döküm: A versatile method that uses sand molds, suitable for both small-scale and large-scale production of complex shapes.

Investment Casting: Precision is central to this process, which uses wax patterns coated with ceramic to produce highly detailed components.

Döküm: This involves injecting molten material under high pressure into metal molds, primarily used for mass production, resulting in smooth-surfaced parts.

Centrifugal Casting: Ideal for producing cylindrical parts, this process rotates the mold at high speeds to ensure uniform material distribution.

Types of Stainless Steel Castings

Stainless Steel Investment Casting

Investment casting, also known as lost-wax casting, is a highly precise and versatile method for producing stainless steel components. First, a wax pattern representing the exact geometry of the desired part is created, commonly used in stainless steel investment casting. The wax pattern is dipped into a ceramic slurry, coating it with a hard ceramic shell. The shell is dried, heated to melt, and then drained to remove the wax. Molten stainless steel is poured into the ceramic shell to form the desired part, achieving very tight dimensional tolerances and fine surface details.

The primary advantage of investment casting stainless steel lies in its ability to produce more complex geometries while maintaining strict tolerances, making it ideal for components with intricate designs or internal cavities. The most commonly cast stainless steels are 304, 316, and duplex stainless steels, as they offer a good balance of mechanical properties, corrosion resistance, and durability. Industry experts note that tight tolerances of ±0.005 inches (±0.13 mm) are typically achievable, suitable for near-net-shape parts requiring minimal machining.

Stainless steel investment casting finds extensive applications across industries such as aerospace, automotive, medical, and construction. Aerospace components, like turbine blades, require stainless steel castings for their ability to withstand extreme temperatures while maintaining strength. In the automotive industry, nearly all precision or engineered parts, including engine components and exhaust manifolds, rely on castings. Thus, investment casting offers design flexibility, reduces waste, and can be cast into various stainless steel alloys, making it one of the crucial manufacturing technologies in modern industry.

Sand Casting Stainless Steel Parts

Sand casting is one of the most versatile manufacturing methods for producing stainless steel castings. This method involves creating molds from a mixture of sand, clay, and water, into which molten stainless steel is poured. It is particularly advantageous for large or structurally complex castings where other techniques cannot achieve intricate geometries. It covers most stainless steel alloys, allowing customization based on mechanical and chemical property requirements.

The sand casting process is cost-effective for small to medium batch projects, as the mold materials are relatively inexpensive and can be reused for multiple cycles. Typically, dimensional tolerances for sand-cast stainless steel parts are around ±0.1–0.3 inches (depending on size and complexity), which are not as tight as those achieved with investment casting. Secondary machining is often required to ensure the final part meets specifications.

In recent years, the sand casting process itself has evolved, incorporating 3D-printed mold manufacturing and new sand binder formulations, shortening lead times and improving mold accuracy. Melting and pouring equipment have also become more advanced, enabling stricter control over alloy composition and pouring temperature, ensuring stainless steel castings are produced to the highest industry quality standards.

Sand casting is widely used when critical part characteristics such as durability or corrosion resistance must be guaranteed. Typical applications include pump housings, valve bodies, turbine casings, and marine hardware. With its cost-effectiveness, material diversity, and evolving precision technologies, sand casting remains a vital method for manufacturing cast stainless steel parts.

Precision Casting Techniques

Precision casting, commonly referred to as investment casting, is a process used across various industries to produce highly complex parts. The method involves creating a ceramic mold around a wax pattern. After the wax and resin are melted out, molten metal is poured into the ceramic mold cavity to form the part. Precision casting is renowned for maintaining tight tolerances, smooth surface finishes, and intricate geometries. Substandard precision cast parts often require secondary machining.

With advancements in modern materials science and automation, the precision casting process has been further refined. The industry has seen increasing use of vacuum casting for handling nickel-based and cobalt-based alloys, imparting properties required for aerospace and medical applications. It is claimed that precision casting can achieve dimensional accuracy of ±0.005 per inch and a surface finish of approximately 125 microinches. Consequently, high-demand components such as turbine blades, prosthetic implants, and automotive parts can be manufactured using this process.

Moreover, modern casting techniques promote sustainability by reducing material waste. Near-net-shape technology ensures minimal excess metal is removed, saving resources and production costs. For foundries seeking to balance precision, complexity, and efficiency in part manufacturing, this remains a preferred process, especially for casting stainless steel alloys.

Advantages of Using Cast Stainless Steel

Corrosion Resistance of Stainless Steel

Stainless steel offers excellent corrosion resistance, which is a primary reason for its widespread use in harsh environments such as marine, chemical, and construction industries. This resistance depends on its chromium content, typically ranging between 10.5% and 30%. Chromium reacts with oxygen in the surrounding environment to form a thin, stable chromium oxide passive layer on the steel’s surface, preventing further oxidation and thereby protecting the stainless steel from corrosion.

Further improvements in stainless steel alloys have enhanced their corrosion resistance. For example, duplex stainless steels combine the advantages of austenitic and ferritic microstructures, offering strong resistance to stress corrosion cracking (SCC) and pitting in chloride-rich environments. Evidence shows that certain grades, including 316L and 2205 duplex stainless steel, can withstand chloride concentrations of approximately 1,000 ppm, significantly higher than standard materials.

Additionally, the addition of molybdenum and nitrogen further enhances resistance to localized corrosion, particularly pitting and crevice corrosion. Research indicates that increasing molybdenum content improves pitting resistance, measurable by the Pitting Resistance Equivalent Number (PREN). Grades with a PREN above 40, such as super duplex stainless steels, are highly effective in harsh conditions like offshore oil and gas environments.

Selecting the appropriate stainless steel grade for different applications, particularly from the 400 series, ensures extended service life, reduced maintenance costs, and superior performance under demanding conditions. All these characteristics make stainless steel a vital component in contemporary engineering.

Durability and Strength of Castings

Castings are renowned for their robustness and durability; industries such as automotive, aerospace, and construction rely heavily on them. Casting enables the production of complex geometries with uniform mechanical properties. Materials like cast iron, steel, and aluminum alloys are favored for their ability to withstand significant mechanical stress, thermal variations, and weathering, with high-quality stainless steel offering even better performance.

In terms of application range, cast iron exhibits excellent compressive strength, often exceeding 550 MPa, making it suitable for heavy-duty applications like engine blocks and construction projects. Aluminum alloys are lightweight with tensile strengths ranging from 200 to 600 MPa, depending on the alloy and heat treatment process. Their use in aerospace and automotive sectors greatly benefits from weight reduction needs. Meanwhile, advancements in casting technologies, primarily vacuum and investment casting, have significantly reduced porosity and defects, greatly enhancing component reliability and performance.

Material properties are comprehensively controlled through a series of standard tests to verify tensile, impact, and fatigue performance, ensuring better long-term performance. This rigorous quality control ensures cast components can withstand demanding environments without compromising structural integrity. Advances in materials science combined with advanced casting techniques have elevated the strength and durability of these critical engineering components.

Cost-Effectiveness of Stainless Steel Investment

Stainless steel can be an economical alternative for various industries due to its long service life, low maintenance costs, and exceptional durability. Its excellent corrosion resistance means it rarely requires repairs and replacements are infrequent, reducing operational costs over time. Data indicate that stainless steel structures can last over 50 years in many applications, particularly in construction and manufacturing, with minimal degradation in material properties. Recyclability is another key feature enhancing cost-effectiveness: stainless steel can be melted and reprocessed into any form without compromising its chemical or physical properties, saving raw materials, especially when compared to some carbon steel castings.

The global stainless steel recycling rate exceeds 85%, demonstrating its economic viability under circular economy principles. Furthermore, advancements in manufacturing technologies such as precision polishing, advanced molding, and innovative processing methods are now focused on optimizing material utilization and minimizing production waste in the manufacturing of various components and products. Given that stainless steel alloys meet stringent financial and operational standards over the long term, industries like transportation and energy favor stainless steel components for applications requiring high performance and sustainability.